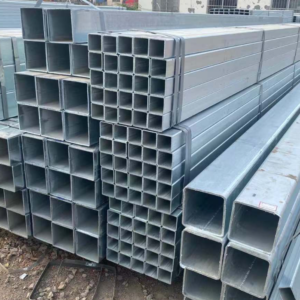

| Material: | A36、A53、A106、A192、ST52、Q355、A210、T12、T11、P5、P9、P91、T22、A333、4140、5135 etc. | |

| Grade(EN): | 1.7220、1.7336、1.2601、1.7380、1.7335、1.0033、1.0116 etc. | |

| Outer Diameter | Seamless:17-914mm 3/8″-36″ | |

| Size | Wall Thickness | 2-60mm SCH10 SCH20 SCH30 STD SCH40 SCH60 XS SCH80 |

| Length | 1-12m as customer requirement | |

| Ends | Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded andcoupling,etc. | |

| Surface Treatment | Bare,Painting black,varnished,galvanized,anti-corrosion 3PE PP/EP/FBE coating | |

| Technical Methods | Hot-rolled/Cold-drawn/Hot-expanded | |

| Testing Methods | Pressure test,Flaw detection,Eddy current testing, Hydrostatic testing or Ultrasonicexamination and also with chemical and physical property inspection | |

| Third Party Inspection | SGS BV MTC | |

| Trade Terms | FOB CIF CFR | |

| Payment Terms | FOB 30%T/T,70% before shipment | |

| CIF 30% pre-payment and the balance to be paid upon B/L (copy) | ||

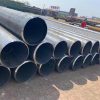

Welded pipe

From super duplex welded tubes to nickel alloys and 6% molybdenum. We ensure that the welded pipes produced by our trusted factories and manufacturers are of the highest possible quality and have been thoroughly tested according to international standards.

Although the joints in welded tubes are theoretically weaker than seamless tubes, the manufacturing methods and quality assurance procedures are now far superior. This means that as long as the temperature and pressure of the welded pipe does not exceed the specified tolerances, there is no reason why it should not perform as well as seamless tubing in a wide range of industries.

Welded pipes are ideal for pipeline products in many different industries, such as petrochemical, desalination, oil and gas, and chemical processing.